The Science Behind It

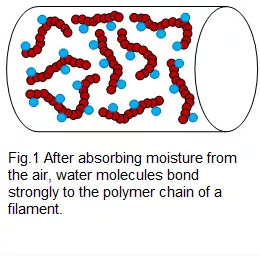

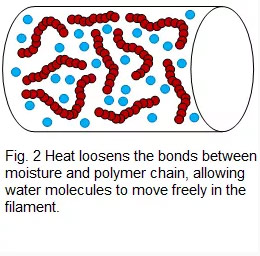

When moisture being absorbed into hygroscopic filaments, the water molecules are attached to the polymer molecule chains of filaments, forming a strong inter-molecular bond. This bond is what makes drying the filament difficult. The desiccant packs coming inside a filament package are not strong enough to break the inter-molecular bond and “pull” the moisture out of the filament. Instead, the desiccant packs help more to prevent water content in a filament from going up other than reducing it. On the other hand, if exposed the desiccant itself will become saturated with moisture and lose its much-needed moisture absorbing capacity. Desiccant packs cannot reduce the water content inside filaments.

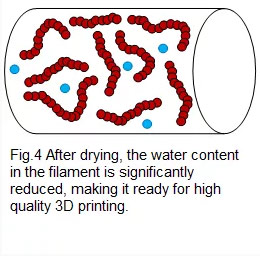

What’s required for drying 3D printing filaments is a dryer that heats up a filament completely, breaks the moisture/polymer bonds, and moves the moisture to the filament surface where it can be carried away, leaving the filament dry and ready for high-quality 3D printing.

The PrintDry filament dryer is based on the following basic parameters of drying.

- Drying Temperature: As the temperature is increased, the molecules inside a filament move more vigorously and this weakens/breaks the moisture/polymer inter-molecular bonds. In addition, heat also causes the air to expand, reducing the concentration of water molecules in it, making the air inside the dryer more able to absorb moisture. The water molecules can travel more freely through the filament at higher temperature. Generally speaking, the higher the drying temperature, the more quickly and thoroughly the filament will dry. However, if the drying temperature is too high, thermal degradation and/or oxidation may occur. Different filaments need different drying temperatures.

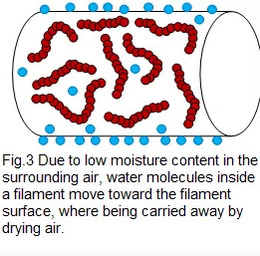

- Moisture concentration differential: This refers to the amount of moisture in the filament versus that in the air surrounding the filament. Surrounding a moist filament with dry (low dew point) air, will encourage water molecules inside a filament to migrate more readily to the surface and eventually being carried away by air.

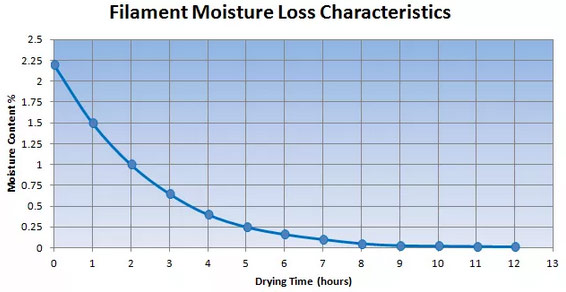

- Drying Time: Filaments do not dry instantly. First, it takes time for the heat to penetrate/distribute throughout the filament interior, especially those deeply buried in the spool. Second, it takes time for the newly freed water molecules to defuse to the surface of the filament.

- Air Flow: Airflow carries heat to the filament and also carries water molecules away.